Vinyl magnet: description, types, manufacturing process. Magnetic Vinyl: Types and Applications

Magnetic vinyl is a sheet material consisting of a magnetic filler (ferrite) and a polymer binder. In Russia, it is also known as magnetic rubber. In the manufacture of such a material, one side of it is magnetized so that relative to its surface, the magnetic field lines are parallel. Due to the alternation of magnetic poles (approximately 5 poles per centimeter) it creates a magnetic effect that allows the material to be securely attached to attractive smooth surfaces, mainly from magnetic metals. Such surfaces have, for example, the case of a computer processor unit, a refrigerator, a car body, etc. As a rule, a magnetic material has a maximum energy attraction of approximately 0.78 106 Gs Oe (6 kJ/m3).

Can be covered with vinyl film of various colors or paper self-adhesive coating. With such a surface, magnetic vinyl can be used for printing. Most often, for these purposes, the method of silk-screen printing, offset printing or embossing is used. Magnetic materials are convenient in that they are easy to stamp, cut (they can be easily cut with ordinary scissors and other mechanical methods). At the same time, this material is characterized by high tensile strength and elasticity. For example, when wrapping a rod with a diameter of 5 cm, magnetic vinyl will retain its structure without cracking.

Scope and conditions of magnetic vinyl application

Magnetic vinyl is widely used in the production of advertising and souvenir products. It is used to make business cards, flexible magnetic advertising symbols, information signs, magnetic souvenirs, toys (for example, an alphabet set for teaching Russian or a foreign language), etc.

Usage magnetic materials allowed at temperatures ranging from 40 to + 70 °C. The maximum allowable operating temperature is + 80 °С. At higher temperatures, vinyl is not recommended. If the material is heated above +240 °C, it may ignite. It is important to note that during the combustion of magnetic material, a sufficiently large amount of smoke is formed, which contains the chemical elements CO, CO2, SO2, HCl, as well as decomposition products of hydrocarbons, including alcohols and aldehydes, which can have a negative effect on the human body.

Magnetic vinyl itself is safe and non-toxic. When used correctly, it does not emit harmful substances. Note that protective goggles should be worn during mechanical processing of the material, since small particles that are formed during the process can get into the eyes and cause irritation.

Material storage conditions

The magnetic vinyl surface can be cleaned using a water-based solution and detergent. Cleaning with acetone or ethyl alcohol is also possible. Other chemicals are not recommended for this purpose, as they may impair the usability of the magnetic material.

Magnetic vinyl can be stored at room temperature and moderate humidity. Under such conditions, it is able to retain its properties for a long time. Almost all products made from this material can withstand many years of use.

When storing the material in the form of a roll, mechanical impacts and sudden temperature changes should be avoided, as this can lead to partial sticking of the layers inside the roll. Magnetic vinyl is best used as soon as possible after purchase, without long-term storage.

Material types

The two main characteristics of vinyl that define its scope are its thickness and finish. The thickness indicator can be from 0.25 to 2 mm. The thinnest version of the material is also called magnetic paper. The thicker the material, the higher its magnetization. Printing houses use magnetic vinyl in rolls, for small businesses they take magnetic vinyl in sheets. As for coating options, modern consumers can buy these types of vinyl:

Magnetic Vinyl Applications

Elastic material with magnetic properties is widely used in the manufacture of advertising and souvenirs. Entrepreneurs are constantly finding new ways to use vinyl. Here are just a few promising examples:

Elastic polymeric material, which includes: magnetic powder (ferrites), polymeric materials, plasticizers. Available with sticky adhesive (self-adhesive) and without adhesive, inkjet coated, white or color coated for solvent and UV curable inks.

Magnetic vinyl has a holding force that is roughly proportional to the thickness of the sheet. Thicknesses of magnetic vinyl from: 0.3 mm to 2 mm. Thin magnetic vinyl is used for attaching light paper products, thick for example, for attaching fairly massive ceramics.

The manufacturing process consists of the following steps:

1. drawing or printing an image on paper, plastic, ceramic or metal

2. one-sided lamination of the printed sheet or varnishing (in case of using paper),

3. sticking this sheet to the magnetic vinyl, cutting out the shape.

Fields of application of magnetic vinyl - advertising, souvenirs, making models and visual aids:

How to choose the material for the magnet???

To make a permanent magnet, of course, it is not enough to take a piece magnetic ores of natural origin. Modern materials for magnets must meet the requirements for each specific product. To understand what material is needed for a particular permanent magnet, you need to answer a few questions:

- What magnetic properties of the material are needed?

- What are the requirements for the physical properties of the material?

- What temperatures must a magnet withstand?

- What are the magnet cost requirements?

Today, a variety of materials are used to make magnets. These are alnico, ferrites, samarium-cobalt, neodymium-iron-boron, iron-chromium-cobalt alloys, as well as materials in the form of a mixture of magnetic powder and some kind of binder component. The bonding material can be rubber, plastic and epoxy resin based materials.

Each of the above materials has both advantages and disadvantages. The properties of materials are the basis for the manufacture of magnets for various purposes.

Let's start the inspection of magnetic materials from one of the oldest...

1. Alnico AlNiCo magnets

Used since the Second World War, it has undeniable positive qualities compared to other materials. It can have a very high remanence, Br, ranging from 6700 to13500 G. The temperature at which the material completely loses its magnetic properties (Curie temperature) for this material is approximately 840 0 C, the temperature stability of this material is very high. The temperature coefficient of induction and other magnetic characteristics is 0.02 (% / 0 C), less than many other available materials. Another important property of alnico is the possibility of forming a magnetic field of high curvature in the material. Alnico's famous horseshoe shape is a twisted magnet with the north and south poles aligned so that they can, for example, lift a steel rod.

Among the shortcomings, it should be noted that Alnico is a very hard and brittle material. It can only be processed by polishing, grinding or EDM. This creates difficulties when used in the composition of the product. Alnico also has a low coercive force, varying in the range of 0.64-1.9 kOe.

2. Ferrites (ferrites of barium, cobalt, strontium ..)

The cheapest magnetic material today is ferrite (ceramic).

This material has moderately high Hcb and Hci values (from 2,500 to4,000 g), which is significantly higher than that of Alnico. Its electrical resistance is also very high. Ceramic materials are usually insulators, while virtually all magnetic materials have moderate electrical conductivity.

The disadvantages of ferrite materials include a lower Curie temperature (about 450 0 C), as well as low temperature stability. The temperature coefficient of ferrite materials is 0.2 (% / 0 C), i.e. they are 10 times less stable than Alnico (-0.02 (% / 0 C)).

Ferrite materials have long been used in the manufacture of electric motors, where a magnetic material with a high coercive force is needed, and for this material it varies from 2,500 to4,000 g, which is quite sufficient for DC electric drives used in industry. At present, ferrites have become widely used in automobile DC motors, power windows, fans, antenna motors, etc. Electric drives in the automotive industry have been the main support of the magnetic business for almost 40 years.

The main advantage of ferrites is their low price. But we should also not forget about the high chemical stability to oxidation, which allows ferrites to retain their properties and appearance without any coating for decades.

3. Magnets Samarium Cobalt (SmCo)

In the late 70s of the last century at the University of Dayton, as part of one of the projects of the US Air Force, the material samarium-cobalt (SmCo) was used. The magnetic field energy of this material turned out to be higher than that of Alnico, and the temperature stability was remarkable. At the same time, it is the most expensive magnetic material available.

The advantage of SmCo magnets is the high remanent magnetization Br (up to11.5 kg), coercive force Hci (from 5.5 to 25 kOe) and high Curie temperature.

Two grades of SmCo are known: 1:5 is an alloy with a Curie temperature of 750 0 C, and 2:17 is an alloy with a Curie temperature of 825 0 C.

SmCo magnets have a good temperature stability of 0.035 (% / 0 C), their temperature coefficient of induction is higher than that of Alnico.

The disadvantages of SmCo magnets are their high cost and fragility. The high price of the material is due to the use of expensive rare earth metals in it. In particular, the samarium purification technology is quite expensive, just like cobalt is quite expensive.

Of the alloys - 1:5 and 2:17 - less expensive (by 10-15%) is the 2:17 alloy, since in it a small part of the cobalt is replaced by iron, and the samarium content is less than in a pure 1:5 alloy. The output of magnets from 2:17 alloy is still 50% higher than from 1:5 alloy. Designed with a 2:17 alloy, magnet systems have more magnetic energy, while a 2:17 alloy does the same work as a 1:5 alloy at a lower cost.

The second drawback of the SmCo material is its brittleness. Customers are generally advised to have SmCo magnets with 1mm radius chamfers.

However, in many military applications where stability and reliability are required and price is less important, SmCo magnets have replaced Alnico.

4. Magnets neodymium iron boron (NdFeB)

Manufacturers began to look for a magnetic material that would have the same magnetic energy as SmCo, but at a significantly lower cost. It has been found that NdFeB alloys have a very high energy product - up to 50-55 MG * Oe - at a significantly lower price than the price of SmCo. Scientific research of a new magnetic material - neodymium-iron-boron (NdFeB) - began in the 80s of the last century, and its widespread use in industry - since 1984.

NdFeB magnets have a wide operating temperature range (from -40 0С to +150 0С), some types can be used up to 200 0С.

The temperature stability of NdFeB magnets is less than that of SmCo magnets - their temperature coefficient of magnetic induction varies from 0.07 to 0.13 (% / 0C) (for comparison, 0.035 (% / 0C) for SmCo). As a result, at temperatures above 180 0C, SmCo magnets can create larger magnetic fields than NdFeB magnets.

To avoid corrosion, the NdFeB alloy is coated with zinc, nickel, copper, or a combination of these materials. In addition, in order to avoid the occurrence of chemically unstable compounds in the structure of the alloy, the manufacturing process is carried out in the absence of air.

NdFeB has a low Curie temperature of approximately 310°C, which can be increased by adding cobalt. However, the use of cobalt leads to an increase in the cost of the material.

At present, NdFeB magnets are very widely used in electric drive motors in computer technology due to their high energy magnetic characteristics. In the 80s of the last century, ferrite magnets were used for these purposes, later - magnets from SmCo. The use of stronger magnets allows the disc drive to be made smaller. Reading and writing devices, the so-called VCM, as well as all disk and spindle motors, use neodymium iron boron sintered magnets. Approximately 60% of the NdFeB magnetic material used in industry is used in computer disk drives.

The susceptibility of NdFeB to corrosion forces the magnets to be coated. Painting, epoxy coating is good as a protection against oxidation, but adds an extra layer between the magnet and other parts of the product. This layer causes additional magnetic resistance in the circuit, similar to resistance in an electrical circuit. Nickel and zinc coatings are most advantageous due to the possibility of applying a very thin layer. Nickel is especially effective in protecting the magnet from air and humidity due to its tightness. In addition, it is one of the cheapest methods of protection against oxidation. As a rule, the thickness of the nickel coating does not exceed 15-20 microns.

At present, NdFeB magnets can be produced with additives from various materials such as dysprosium, cobalt, niobium, vanadium, gallium, etc., which leads to an improvement in the stability of the magnet from the temperature and corrosion points of view. These modified magnets can be used up to temperatures of +220 0C.

5. Magnetic plastics or polymer magnets

Magnetoplastics are made by mixing magnetic powder and some kind of binder. Rubber, acrylic, polyamide, thermoplastic, plastic, vinyl, epoxy resin, PPS, etc. can be used as a binder.

The magnet is made from a mixed mass in the following ways:

Rolling into a continuous sheet by pressing between two rollers (calendering).

The heated mass is formed by extrusion through a hole of a certain section (extrusion).

The heated mass is injected into the die, where it cools until hardened, then the die is opened and the casting is removed (casting method).

The coated magnetic powder is placed in the die cavity and compressed tightly under high pressure (pressure pressing).

Magnetoplastics have physical properties typical of a binder material. The rubber magnetoplast is flexible, does not crumble or break. Epoxy-based magnetoplastics have good resistance to oils, gasolines and common solvents. The main binding materials have the following characteristic features:

The limit of use by temperature corresponds to the temperature at which the binder loses its hardness (150-180 0 C).

Leakage, due to which water and air can penetrate into the material, which affect the magnetic properties of the material.

The binder can swell, absorb moisture and, as a result, change its size and lose strength.

The correct choice of binder material can be important to minimize negative effects.

Brass, aluminum, steel, and even high-temperature plastics can be used in the process of pressing these magnets, when magnetic connections are formed by mixing magnetic powder and a binder material.

By adding two components to a mold, a product containing two different materials can be made. It can be two magnetic materials or a mixture of magnetic materials and plastic. There is a variant of this process called multi-stage injection injection, where dissimilar materials are pressed sequentially. This technology often gives better results in terms of magnetic properties than simultaneous pressing.

The described processes make it possible to create both simple and very complex forms of magnets; with direct, radial and multipole magnetization.

The operating temperatures of magnetoplastics are low compared to the operating temperatures of sintered magnets. The use of different magnetic powders makes it possible to obtain a "hybrid" magnet with one or another set of properties. Particularly useful are hybrids, which are mixtures of ferrite powder with a small amount of rare earth powder, usually NdFeB. A different percentage of the components of such a hybrid allows you to obtain the necessary characteristics.

One of the disadvantages of magnetic plastics is the upper temperature limit of use, determined by the temperature state of the binder material. This value usually ranges from 80 0C to 220 0C. Polyphenyl sulfide (PPS) has a high operating temperature with minimal absorbency and high resistance to the harmful effects of oils and other petroleum products. The automotive industry has already started producing magnets using PPS. The use of Nylon 6 and 12 as binders also gives good results.

Thermoelastic magnetoplasts have an upper temperature limit of about 80 0 C.

In the production of magnetoplasts and magnetoelasts, NdFeB powders, ferrites, Alnico and SmCo, as well as their various combinations, are used.

One of the most promising areas of application of magnetoplasts is the creation of compact and highly efficient electric motors and drives, as well as various types of sensors. The ability to create magnets of the most complex shape and high magnetization, as well as good mechanical properties, are the main competitive advantages of magnetoplastics.

How to choose a magnet?

There are two main selection criteria - cost and temperature stability.

The cost of a magnet is almost always the main selection criterion. The price is one of the main quantities characterizing a magnet, along with such information as the type of material, size, shape, direction of magnetization, etc.

The following magnet selection scheme is proposed:

Consider ferrite magnets first because of their low cost.

If efficiency is especially important, use NdFeB-based rare earth magnets.

When high reliability and stability are required, use SmCo based magnets or AlNiCo single crystal magnets.

If the magnets need to be long (relative to their diameter or width), choose Alnico. Make short magnets from ferrites and a family of rare earth magnetic materials.

Make small magnets of complex shape and magnetization from magnetic plastics.

Section List:

Rental of production equipment

Labeling of industrial products, production of printing or souvenir products is an excellent core business, but often manufacturers have a temporary or even one-time need for equipment for the above purposes.

All About Inks and Continuous Ink Supply Systems

Printing with sublimation ink

You can purchase the most modern and high-quality sublimation inks from us, designed for use on inkjet printers.

Features of printing with UV curable ink

UV-curable inks are completely unique printing materials, gaining more and more popularity every year due to their advantages.

Ink for plotters

In the Forsign online store you can purchase sublimation, solvent, eco-solvent and UV-curable inks for Mimaki, Roland, Mutoh, Epson large-format printers and plotters.

pigment ink

Such inks first appeared much later than conventional dye-based inks, as a result of long and painstaking work by Hewlett-Packard researchers.

Sharpening machines

Milling cutters for CNC machines

In this article we will talk about the variety of cutting tools used on engraving and milling machines.

Application of grinding machine VERTEX VEG-13A

We are pleased to offer you the most modern industrial equipment for milling and engraving, including the necessary related installations. For example, the VERTEX VEG-13A grinding machine is an absolutely indispensable device in the workshop.

SHARPENING MACHINES VERTEX

When working on engraving and milling equipment, the quality of the cutting tool plays a primary role

Sharpening machines

In the Forsign online store you can purchase high-tech machines for sharpening face and cone cutters manufactured by Vertex (Taiwan).

Instructions for heat presses

Adkins Beta Mug Heat Press Instruction Manual

Mug heat press is designed to transfer images to ceramic mugs by thermal transfer and sublimation.

Cliche for embossing and stamping. Production, materials, accessories, etc.

A few words from history;

Blind embossing (blind);

foil stamping;

Relief stamping;

Material for making clichés;

Cliche from Magnesium;

Cliche from Copper;

Calculation of the cost of a cliché;

geometric fidelity.

Laser engravers (laser engraving machines)

Laser engraving on two-layer plastic

Forsign offers a wide range of modern and high-quality two-layer plastics produced by Gravograph, LaserFlex and Rowmark. What is the technology for their use? What products can be made from them?

Materials for laser engraving

At present, it has become possible to manufacture a huge range of products from a wide variety of materials on laser machines and engravers.

Capabilities of Gravograph laser engravers

Laser engravers of the French brand Gravograph are the equipment with which you can take your business to the next level.

Product marking with a laser

The reason for the huge popularity of this method today is the combination of ease of implementation and high quality processing.

Small Business GCC Engravers

Forsign offers an extensive selection of high-quality laser engravers from the world's leading brands, including more than 20 models from the Taiwanese brand GCC. In this article, we will tell you about what business opportunities open up when using this equipment.

GCC laser engravers

The Taiwanese company GCC produces a wide range of high quality laser engravers in a variety of technical parameters. And we have the most modern and practical models.

Laser engraver Laser Pro Venus V12 GCC

This model of the laser engraver from the GCC company is threatened with incredible popularity among specialists in the field of souvenir production!

SignCut laser engravers

Forsign is the official dealer of a number of manufacturers of laser engravers, including SignCut, a Chinese company.

Plaquettes for laser engraving - the basis of a status souvenir

Modern technologies make it possible to simply and inexpensively produce spectacular memorable souvenirs - award boards.

Laser engravers - Opportunities.

Laser engraver (laser engraving machine)- belongs to the category of expensive equipment ...

Laminators

Cold Laminating Film

The Forsign catalog includes a wide range of high-quality cold lamination films from world famous brands: Oraguard, Pronex, Maunt.

Batch laminator

All laminators can be divided into two main types: batch and roll. Bag laminators use a plastic bag of a certain size for lamination.

lamination

Lamination is the process of coating a printed sheet with plastic. The document is hermetically soldered into a double-sided bag of a special film for lamination, under the influence of heat transferred from the heating element of the laminator.

How did the laminator come about?

Now you won’t surprise anyone with a laminating machine: they are in printing houses and photography studios, and even in some offices. However, few people know how it all began.

What is a laminator?

The laminator is the equipment intended for protection of information against mechanical damages. There are many modifications and types of laminators....

Magnetic vinyl

The Forsign company offers high-quality magnetic vinyl in roll and sheet variants.

Fields of application of magnetic vinyl

Forsign offers a high-quality, magnetic, flexible polymer sheet for the production of magnetic souvenirs and POS materials, magnetic tape in rolls for attaching various information or exhibition stands

Print materials

Braille sign making

Every year more and more attention is paid to the organization of an accessible environment, and for any public facility it is mandatory to install signs and signs for visually impaired and blind people.

Milling facades from MDF

Currently, MDF boards are a very popular material for the manufacture of furniture facades of varying complexity.

Sublimation printing on ceramic tiles

Currently, the technological possibilities for decorating ceramic tiles are almost limitless. And sublimation printing is one of the most promising options.

Solvent ink

In this article, we will talk about some of the most effective and modern inks used in large format printing.

Sublimation for mugs

With the help of sublimation printing, you can apply any image to any product! Today we will talk about sublimation on ceramic and glass mugs.

Sublimation ink InkTec

At Forsign you will find the most modern and reliable inks for various types of printers, and InkTes products occupy a special place in our catalog.

Honeycomb tables for engraving machines

At Forsign you will find all the necessary equipment and accessories for the most efficient operation of engraving and milling machines. Including cell tables.

sublimation on metal

Our catalog contains high-quality metal plates for sublimation printing. We will talk about this technology in the article.

Range of UV curable inks

UV curable ink is becoming more and more popular in today's printing industry due to its many benefits. Our company has a fairly wide selection of such inks.

Everything for glass matting

In our company you can buy all the necessary tools and materials for glass matting, which allows you to achieve incredible beauty of images on glass without the use of paints.

How to choose plotter knives

The range of high-quality knives for cutting plotters in our company is extremely wide, and therefore we are pleased to tell you about the basic rules for selecting these accessories.

Oracal film for plotter cutting

The most intricate image and logo templates will be cut neatly and accurately by professional cutting equipment using Oracal Self Adhesive Film designed for plotter processing

Metal printing technology Graverton

This method of transferring images to special metal plates is used to create a variety of products, including diplomas and certificates.

Film for stained glass

Increasingly, the windows of restaurants, museums and exhibition centers are decorated with pseudo-glass stained-glass windows in a medieval style.

Oracal calendered film

Low price is the main, but far from the only advantage of calendered film over cast film.

Oracal car film

Every day restyling of a car with the help of self-adhesive vinyl films becomes more and more popular.

Film for sublimation

Sublimation refers to the process of dyeing synthetic materials with gaseous ink.

Sublimation Ceramic Tile

Modern interior design strives for uniqueness and personalization. Therefore, exclusive decorative panels made of sublimation tiles are widely used in it.

Consumables for sublimation printing

In the online store "Forsign" you will find a comprehensive selection of materials for sublimation printing: thermal transfer film, thermal transfer paper, blanks for printing (mugs, plates, t-shirts, watches, puzzles).

About companies - manufacturers of equipment and consumables

Roland equipment

Forsign presents original products of the famous Japanese brand Roland, which enjoy well-deserved popularity all over the world.

About Roland

Forsign has a wide range of advanced equipment made in Japan by Roland. And today we will tell you more about this brand!

About brand Mimaki

In our company you will find high-tech printing equipment manufactured by leading world brands, including the Japanese Mimaki trademark.

About Graphtec brand

Our company has a wide range of high-tech equipment produced by the famous Japanese brand Graphtec. We want to tell you about it.

Paste for matting glass ArtGlass

The Forsign company offers you to purchase the original ARTGLASS paste for glass matting at a competitive price!

A complete palette of Megaink Solvent Inks in the Forsign catalog

We are glad to offer you high-quality consumables for large-format printing - Megaink solvent ink (Czech Republic)!

A. Adkins & Sons Limited (Adkins)

A. Adkins & Sons Limited (Adkins) manufactures thermal transfer and sublimation presses.

Equipment and consumables for the production of badges

Everything for the production of premium products

In the Forsign online store you can purchase all the necessary equipment, blanks and consumables for the production of premium products.

Badge making equipment

In Forsign you can purchase a full range of necessary equipment and consumables for the production of plastic, metal, wood and laminated paper badges.

Plastics for engraving

Rowmark Plastics for Laser Engraving

Acrylic plastics Rowmark American production - a unique material for laser engraving and mechanical milling.

Photo studio equipment

Modern photo studios cannot do without such additional equipment as laser engravers, large-format printers, plotters, sublimation complexes, and routers with the function of portrait engraving.

Cutting plotters

Types of knives for cutting plotter

The production possibilities of modern cutting flatbed plotters are very wide - especially given the variety of knives used. We will talk about them in this article.

How to adjust the cutting plotter knife

Competent adjustment of pressure of a knife of the cutting plotter is a pledge of high-quality and exact cutting of a film. In this article, we'll show you how to properly set this up.

Home scrapbooking plotters

The range of Forsign is constantly expanding, and today you can purchase from us not only professional industrial equipment, but also specialized machines for home use in a creative and exciting hobby - scrapbooking.

The best plotter for your hobby - GRAPHTEC CAMEO NEW

One of the most interesting novelties in our catalog of professional equipment is the cutting plotter GRAPHTEC CAMEO NEW. And this is a great option for scrapbooking!

Unlimited possibilities of the COMAGRAV DIGI 3450 flatbed plotter

Undoubtedly, the most expensive COMAGRAV model in our catalog is the DIGI 3450. In this article, we will explain why its high price is fully justified.

Cutting plotter "Roland"

Equipment from the Japanese company Roland DG is one of the most popular cutting plotters on the market due to its reliability, versatility and the highest quality of products.

Cutting plotter Graphtec Silhouette Portrait

Compact desktop cutting plotters at the moment are a necessary attribute not only for souvenir workshops and ateliers

Cutter Silhouette Curio

In addition to powerful professional cutters capable of performing a wide range of contour cutting operations on various materials, modern manufacturers offer small cutting plotters that are great for home hobby centers.

Laser cutting plotter

Laser equipment is a relatively new, but already widely used type of device in the modern world, designed to perform a variety of engraving operations on various types of materials, as well as through and contour cutting.

How to cut on a plotter

Contour cutting on a modern plotter is a simple process, but there are a few points that you should pay attention to in order to avoid mistakes and inaccuracies when creating a finished product.

Desktop cutting plotter

In the field of manufacturing souvenirs and printing products, it is almost impossible to do without a cutter, but often there is a need to save space

Cutter Silhouette Cameo

Equipment for contour cutting of materials of various types and densities is a necessary attribute not only of large industrial enterprises, but also of small workshops, ateliers, souvenir shops and even home hobby centers.

TABLET PLOTTER COMAGRAV (CZECH REPUBLIC)

Over the years, plotters have made life easier for professionals in various fields of activity: from engineering to souvenirs - and over time they do not become less in demand.

Scrapbooking plotter

In Forsign you can purchase not only commercial cutters, but also plotters for individual use.

Graphtec flatbed plotter

Graphtec Japanese flatbed cutters are widely used in the production of cardboard packaging, all kinds of prototypes, patterns and templates from solid and thermoplastic materials.

Film cutting plotter

In the Forsign company you can buy inexpensive plotters for high-precision cutting and perforation of film materials.

Spare parts for plotters

At Forsign you can purchase consumables, accessories and spare parts for cutting plotters.

Mimaki cutting plotters

Products of the Japanese company Mimaki Engineering Co., Ltd. successfully implemented on the world market for about forty years.

Used cutting plotter

Modern cutters have a fairly long service life, and with proper use they can work without interruption for a long time, while absolutely not losing the necessary qualities.

GCC Professional Cutting Plotters: Jaguar Series

Forsign is always happy to offer you the best range of reliable and functional cutting plotters.

High-precision and inexpensive knives for plotters from Forsign

Do you need really high-quality accessories for cutting plotters? We will be happy to help you make the right choice.

Offset cutting plotter.

OFFSET (in English: compensation, counterweight, compensation). Offset is indicated on the box with knives for the cutting plotter.

The working principle of the cutting plotter

You prepare the image in any vector program (for example, CorelDRAW, Adobe Illustrator) or in the program that comes with the plotter.

Cutter is a cutting plotter!

A cutter, from the English cutter - a cutter, is a computer-controlled device for cutting (plotter cutting) images and contours from thermal transfer and vinyl film, self-adhesive paper, and other roll and sheet materials.

Graphtec plotters

It is no secret that many Japanese high-tech companies are well known all over the world, except for Russia. Why are the Japanese in no hurry to enter our market?

Self-adhesive films

ORACAL films

The catalog of self-adhesive films of the leading manufacturer ORACAL presents a huge variety of options, and we will tell you about the most popular ones in this article.

Self-adhesive films

At Forsign, you will find a huge selection of self-adhesive films for use in the decoration and design of various objects. And we will tell you about its benefits.

Self-adhesive stained glass film

Making stained-glass windows for insertion into windows and doors is a time-tested, but by no means a cheap way to decorate rooms.

ORACAL 352: metallized polyester film

On the pages of the Forsign catalog you can always find various types of self-adhesive films of the brand Orafol (Germany), including ORACAL 352.

Self-adhesive fluorescent film

Among the amazing range of films produced by the Orafol brand (Germany) and sold by Forsign, you will also find fluorescent films among them.

Sandblast Film

Forsign offers its customers an excellent range of products for the processing of various materials.

Stained glass film ORACAL 8300

We present to your attention the products of the company "Orafol" (Germany) - stained glass film Oracal 8300.

Recommendations for the use and application of calendered self-adhesive films MACal 8300Pro/8900Pro from MACtac (Belgium)

1. Features of MACal 8300Pro and 8900Pro films

2. Storage

3. Pruning

4. Sample

5. Using the mounting tape

6. Cleaning the surface for application

7. Applying the MACal film to the surface

7.1. wet method

7.2. dry method

7.3. Air bubble removal

8. Film removal

8.1. 8300Pro

8.2. 8900Pro

9. Special recommendations for transport applications

10. Special Notes for Window Applications

11. Specific surfaces

Surface preparation before applying applications (part 2)

Surface preparation before applying applications (part 1)

Work with painted surfaces, stained-glass windows, plastics, fiberglass, banner fabrics.

Thermopresses

How to work with baseball heat presses

Baseball heat presses are special equipment for applying images to hats (caps, hats, baseball caps, etc.), as well as to convex parts of clothing. We will talk about it in this article.

Mug heat presses: technology, features, features

Our catalog contains several of the most modern models of mug heat presses manufactured by A.Adkins and Sons, Grafalex, PressTec, TheMagicTouch, Transfer Kit. What is this equipment?

Forsign has a wide range of modern and functional heat presses of various types, and one of the most practical options is heat presses for flat surfaces.

MODERN GILDING PRESSES

To obtain beautiful and sought-after printed products, standard design is not always enough: more and more manufacturers are resorting to various types of post-print processing of products.

Our heat press prices

The cost of presses for sublimation and thermal transfer in our online store varies in the range of 10,330-1,780,260 rubles. Why do some models cost 10 thousand, and others almost 2 million? Let's figure it out!

Our prices for embossing presses

The cost of embossing presses in our catalog varies between 33,453-402,710 rubles. More than 10-fold variation is due to the functionality of various models.

Spare parts for heat presses

Our online store offers a wide range of universal spare parts and accessories for all brands of heat presses.

Mugs for sublimation

It's hard to come up with a more versatile gift than a mug with a commemorative picture or a funny inscription.

Mug heat press PressTec PTM160

Purchasing a Mug Heat Press PTM160 (manufactured by PressTec) will open up wide prospects for the production of high quality products.

The widest selection of molds for 3D vacuum heat press

Be sure to check out the 3D Vacuum Press Accessories section of our catalog! You are sure to pick up a lot of useful devices to expand the possibilities of your production!

Mug heat press Insta HTR-616 TS

A thermopress for making souvenir mugs from Insta will become your reliable assistant! Many Forsign customers have already seen the efficiency of this machine.

Rotary thermopress economy class PressTEC PT230

Forsign sells the widest range of thermal presses of various categories. Extremely popular are heat presses for flat surfaces.

Embossing presses

The use of embossing presses in your work will significantly increase the demand of buyers for your printed products.

Universal heat presses

Is your activity related to the production of small circulations of souvenirs? In this case, the ideal solution would be to purchase universal heat presses from Forsign!

Baseball heat presses

For baseball cap heat presses, the working convex surface has a radius convenient for thermal transfer to baseball caps (caps) and sleeves, for example, workwear

Heat presses for flat surfaces

Thanks to a flat thermal press, you can transfer images to T-shirts (T-shirts), tiles, mouse pads, textiles, puzzles, leather, metal, etc.

Thermal transfer

Thermal transfer film for fabric

You will find materials for thermal transfer to fabrics from the world's best manufacturers at Forsign

READY SOLUTIONS FOR BUSINESS: THERMAL TRANSFER EQUIPMENT

The business of designing products using sublimation printing has been and remains not only extremely interesting, but also quite profitable. The scope of application of thermal transfer of images is extensive, moreover, it is increasing almost constantly.

T-shirts for sublimation

At the moment, the T-shirt is perhaps the most popular type of clothing among people of all ages.

Thermal transfer printing equipment

At Forsign you can purchase high-tech printers and thermal presses for sublimation printing.

Thermal transfer film MasterTex OSP PU

Thanks to the extensive color palette of smooth MasterTex OSP PU flex films, you can easily implement any ideas for the production of products in your production.

The Magic Touch, Germany is a manufacturer of thermal transfer materials.

The Magic Touch was founded in 1989 in Frankfurt as a manufacturer of thermal transfer papers for color laser printers and copiers. Since then, the company has been constantly expanding and modernizing. A lot of research work has been done. All this contributed greatly to the expansion of the range of products.

The largest manufacturer of heat presses is Insta Graphic Systems, USA.

Insta Graphic Systems is a thermal transfer press company. In 2005 the company celebrated its 45th anniversary. This is the age that speaks of the company's consistently strong position in the market.

Thermal Transfer Technologies

Thermal transfer flex film

High-quality thermal transfer film with a smooth surface (flex) opens up the widest possibilities for creating various products: from uniforms to souvenirs

Thermal transfer/sublimation latte mugs: in-demand products for cafes and restaurants

The latte coffee drink is served in many establishments. You will find latte mugs (with the possibility of drawing images) in one of the sections of our catalog.

Materials for thermal transfer and sublimation from Forsign - part 1

Forsign is pleased to offer its customers an excellent range of high-quality and inexpensive products for thermal transfer.

An overview of all thermal transfer technologies (thermal transfer) on textiles.

This article describes all currently available thermal transfer technologies for textiles, their advantages and limitations. We hope this article will be useful to you and help you make the right choice.

Testing OKI printers for printing on The Magic Touch thermal transfer paper.

Our customers often have a question - which printer is best suited for printing on The Magic Touch thermal transfer paper? As practice has shown, when working with some printers, there are difficulties with the passage of thermal transfer paper through the fuser (the oven where the toner is fixed). The world-famous manufacturer of thermal transfer paper The Magic Touch on the main page of its official website recommends using color LED printers of the C5000 series from OKI Printing Solutions for printing on most of its types of thermal transfer papers.

Thermal transfer (thermal image transfer to fabric)

There are several ways to thermally transfer an image to a fabric. Consider the method using ACE-301 thermal film for cutting and thermal transfer. Due to the highest durability of the image, workwear and sports uniforms are usually personalized in this way.

Sublimation with an inkjet printer (image transfer to various surfaces).

Sublimation printing technology allows you to quickly apply an image to surfaces containing at least 50% synthetics. Flags, mouse pads, mugs with spec. coated, MasterTon metal, etc.

The essence of the technology: special dyes are sublimated and interact with the polymer substrate.

The image (text, graphics) that needs to be transferred is typeset in any graphic program on a computer.

MasterTon technology - transferring graphics to metal using a laser printer

Masterton technology was invented in the USA and is designed to instantly transfer a graphic image to metal. To begin with, the image (text, graphics) that needs to be transferred to metal is typeset in any graphic program on a computer.

Frequently Asked Questions about Masterton Technology

What is MASTERTON technology?

What equipment is needed for MASTERTON technology?

What consumables are needed?

Positioning on the Graphtec cutter (cutting according to printed).

Often, when printing on self-adhesive materials, the task arises to cut the image along the contour. In large-circulation printing, this is done using die-cutting. It is unprofitable for small and medium circulations. What if you have many different circuits? How to do it? The Japanese corporation Graphtec offers a turnkey solution.

MASTERTON technology (graphics on metal) using an inkjet printer.

MasterTon technology allows you to quickly apply a full color image to specially coated metal plates.

ChromaBlast™ technology - applied to light cotton

ChromaBlast™ is the ultimate system for decorating light cottons

Sawgrass is at the forefront of modern digital printing technologies for transfer to light cotton products. Use Sawgrass technology to transfer images in full color to T-shirts, baseball caps, bags and more.

Glassmoz glass frosting technology

Paste glass frosting technology

Matting glass or mirrors is very simple and fast - using special materials, in particular Glassmoz paste, available in our company at attractive prices. And today we will tell HOW this type of matting is carried out.

Glass frosting technology

Matting glass and mirrors allows you to create truly unique products, but the main thing is to choose high-quality materials and equipment for work. Special modern matting liquids guarantee an excellent result if you follow a simple instruction.

Glassmoz technology - Glass matting. Part 3. Gel AntiGlassmoz.

Water-based AntiGlassmoz gel, after curing in air, forms a protective film on the glass that prevents the work of Glassmoz paste or liquid. The gel can be applied to the glass with a brush, through a template or mechanically. The gel is initially green in color and becomes clear as it dries. Drying time depends on the thickness of the layer.

Glassmoz technology - Glass matting. Part 2. Glassmoz liquid.

Glassmoz fluid can be used repeatedly and mattifies objects of large area or complex shape, when it is difficult or irrational to use Glassmoz paste.

Glassmoz technology - Glass matting. Part 1. Paste Glassmoz.

The unique American matting technology allows you to personalize almost any glass, mirror, ceramics, thereby emphasizing the uniqueness of your corporate identity.

Paper shredders

Are paper shredders afraid of staples?

Most modern professional shredders are equipped with special knives or blades for shredding not only paper, but also more durable materials.

History of the paper shredder

Paper shredders or shredders have become actively used for government and military purposes.

Why do we need document shredders and what benefits do they bring?

Documents left carelessly, even if they are wrinkled or torn, are a potential source of trouble. Once in the wrong hands, they can cause serious financial, moral or any other damage.

Document shredders

Documents are destroyed by their mechanical shredding. A wide variety of document shredders allows you to destroy information on almost any medium: on paper, cardboard, plastic cards, floppy disks, CDs, audio cassettes, microfilms.

Photo wallpapers and frescoes

Veika wallpapers

Here you can buy magnificent wallpapers of Lithuanian-Belarusian production Veika DecoJet - high-quality, modern, practical.

Frescoes for printing Arto di Fresco

We offer the most beautiful, refined and practical materials for decorating a home, office, apartment, restaurant, salon, boutique and any other room - frescoes for inkjet printing on Arto di Fresco plotters.

Wall mural DigiFort

In our company, you can buy high-quality DigiFort large-format photo wallpapers supplied directly from the Dutch brand BN International. And this is a luxurious material for decorating any room!

Frescoes for printing

In the Forsign online store you can buy original and analog fresco paintings by Arto di Fresco.

Everything for the production of photo wallpapers

In the Forsign online store you can purchase a textured base for Digi Fort photo wallpapers from BN International (Netherlands), Decojet from Veika (Lithuania / Belarus), as well as eco-solvent and UV printers for printing on them.

CNC milling and engraving machines

How to engrave stainless steel on a CNC machine

Stainless steel is a relatively hard material. It is engraved according to certain rules.

Milling machines Clever

One of the novelties of our catalog is modern CNC milling machines manufactured by the Russian brand Clever. We will tell about them today.

How to choose a machine for a new milling production

The selection of the right equipment in accordance with the goals, conditions and nuances of the future production is not an easy task. We will suggest the main selection criteria.

Chip removal systems for CNC milling machines

Milling involves the formation of a sufficient amount of waste from the processing of any materials

In this article I want to tell you how you can make a cute fridge magnet with a photo. And not only to make, but also to profitably sell.

My site was originally dedicated to sublimation printing. But this does not mean at all that you can earn money only by selling mugs, plates, puzzles and other sublimation products. There are a lot of ideas! This includes thermal transfer and the manufacture of watches with a photo portrait and the printing of various calendars and much, much more.

The first article about magnets.

What attracts me most about making magnets from vinyl is simplicity (no equipment is needed) and a chic markup in price. Judge for yourself - a magnet measuring 65 x 90 mm costs me less than 5 rubles. I sell it in kindergartens for 120 rubles!

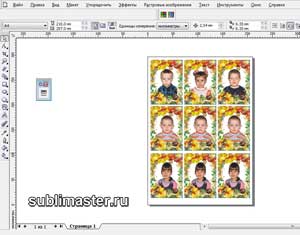

Magnets are different - plastic, metal, sunset. We will make a magnet based on magnetic vinyl. It looks like this:

In a nutshell - this is the most common photograph pasted on magnetic vinyl.

Choose any photo frame and insert a photo of the child. You can draw a photo frame yourself or download it from the Internet. Don't forget about copyright. Not all authors allow you to earn on their frames and templates.

To make a magnet, we need the simplest tools:

This is a small piece of glass, a stationery knife and a metal ruler. And it's all? - you ask! Yes, this is enough to make good money. You don't even need to have your own printer. You can always order photo printing on the side. And your magnets from this will become more expensive not much at all. Later we will count everything.

A few words about magnetic vinyl. It is sold in rolls, usually 30 meters. Such a roll is not only quite expensive, but also very heavy. And this increases the cost of delivery for those who order vinyl by mail or through a transport company. Those who have the Zenon company nearby are more fortunate - they will sell at least half a meter of magnetic vinyl there. Agree, it is very convenient.

Magnetic vinyl is available in different thicknesses. I recommend purchasing vinyl no thinner than 0.7 mm for making magnets. Thinner vinyl magnets look cheap and not solid.

Also, magnetic vinyl comes with an adhesive layer and without an adhesive layer. With an adhesive layer, it has a protective film and, with an equal thickness, costs a little more.

You just have to choose a link:

Magnetic vinyl with adhesive + regular photo on paper

Magnetic vinyl without adhesive layer + photo on self-adhesive photo paper.

I will use the second option. I have 0.75mm glueless and Privision inkjet vinyl on hand.

So, let's start making our magnets.

I think it will not be difficult for you to find a nice photo frame for you. Let's assume that you already have it. Adjust the photo frame to the size you need - I have 65 x 90 mm. With this size, 9 magnets are placed on an A4 sheet. Of course, you can choose absolutely any size.

You also took pictures of the children. It remains to insert the photos into the frame. This can easily be done with or .

By the way, a large section will soon appear on the site about how to photograph children in kindergartens and schools and how to process photos. Don't forget not to miss the announcement.

Photos are inserted, now they need to be placed on the sheet and printed. You can use Photoshop for this, but I like CorelDraw. I import one photo frame at a time and place it on A4 sheet. If more than one magnet is ordered, I duplicate the required number of times.

All photo frames are placed, self-adhesive photo paper is inserted into the printer. Sending a printable! We print with regular water-based inks.

Now we will stick photo paper on magnetic vinyl. I pre-cut it into A4 sheets. More precisely, they turn out to be slightly smaller - 20.5 x 29 cm. The width of a roll of magnetic vinyl is 61.5 cm. I cut it equally into three parts. And I specially reduce the length a little, with my sizes of magnets this is quite enough. You also try to calculate everything so that there is less waste.

For photo paper to lay flat on vinyl without bubbles or creases, just watch how I do it and repeat.

First, turn the sheet face down and fold back the protective paper about 15 mm along the short edge of the self-adhesive.

Now we turn the sheet over and, holding the edge with the folded paper (not letting it stick), place the sheet evenly on the magnetic vinyl.

With the sheet positioned as desired, carefully glue the edge of the sheet to the vinyl and iron well with a dry, soft cloth.

Now our sheet is securely attached to the magnetic vinyl and will not move anywhere. We place our left hand under the sheet, grab the edge of the protective paper and begin to gently pull it to the side, exposing the adhesive layer, and with the right hand, with the help of a rag, smooth the sheet to the vinyl with translational movements up and down.

So we smooth it to the end.

Set the resulting sandwich aside for 15 - 20 minutes so that the adhesive layer grabs well. Now the magnets can be cut. A reciprocating cutter is ideal for this purpose, but you can do just fine without it.

A metal ruler and a clerical knife are what you need. In order for the knife to cut rather than tear the paper on the vinyl, keep the angle of the knife as close to the surface as possible.

Update the knife blade by breaking off the dull part. I usually do this after cutting the next A4 sheet.

Here are the first nine magnets ready.

I put each magnet in a separate bag. I have them 75 x 120 mm. This bag costs a penny, and parents really like the individual packaging.

That's the whole process. As you can see, nothing complicated. Now let's do some math.

I bought magnetic vinyl without glue 0.75 mm thick at 310 rubles per linear meter (width 0.61 cm), which is 504 rubles per square meter or 30.3 rubles per A4 sheet (rounded up to 31 rubles).

I bought a self-adhesive for 100 rubles for 20 A4 sheets. So one sheet costs 5 rubles.

31 + 5 = 36 rubles.

36 rubles: 9 magnets = 4 rubles apiece!

Let me remind you that I sell them for 120 rubles. I know that some people sell similar magnets for 150 rubles.

Now a few words about quality. Water-based inks have a serious drawback - they fade rather quickly. Especially compatible inks. If your customers' refrigerator is located by the window, then the magnet on its door may fade in a year. In this case, I would advise you to print the photos in a photo lab and glue them onto vinyl with an adhesive layer. In this scenario, the cost of your magnet will increase by 2 - 3 rubles, but it will not fade over many years.

Alternatively, the magnet can be covered with a thin cold laminate (laminating film). This complicates the process a little, but the magnet looks just great!

You can also purchase an inexpensive corner cutter and trim the corners of your magnets nicely.

In a word, I gave you an idea. How you put it into practice is entirely up to you. Now you know how to make a photo magnet. Take my word for it, such magnets are in constant demand in kindergartens and schools!